Reliable Hot Dip Galvanizing Plants & Services Near You

OUR OFFICES

KHASRA NO – 134/9/2, VILLAGE-BARHANA TEHSIL-BERI, JHAJJAR HARYANA – 124107

+91-9817975382 / 79

OUR BROCHURE

| Frequency | 50/60 Hz |

|---|---|

| Phase | 3 Phase |

| Automation Level | Fully Automatic/ Semi-Automatic |

| Pipe Size (Nb) | ½ Inch To 12 Inch |

| Pipe Length | 4 To 12 Meters |

| Zinc Coating | As Per Is & Bs Standard |

| Production Capacity | 2000 To 6000 Tons Per Month |

| Capacity | 4-8 Mt Per Hour For Pipe Galvanising |

| Specification | As Per Api/Is/Astmbs Standard |

| Fuel | Furnace Oil With A Net Calorific Value Of 10000 K. Cal./Kg Or Gas |

| Zinc Consumption | Averages 6 T O 7% Depending On Pipe Size |

| Zinc Efficiency | Average 6 M From Floor Level Zinc Dross: 8 T O 10% |

| By Product Of The Zinc Used | Zinc Dust:10 T O 16% Zinc Ash:16 T O 18% |

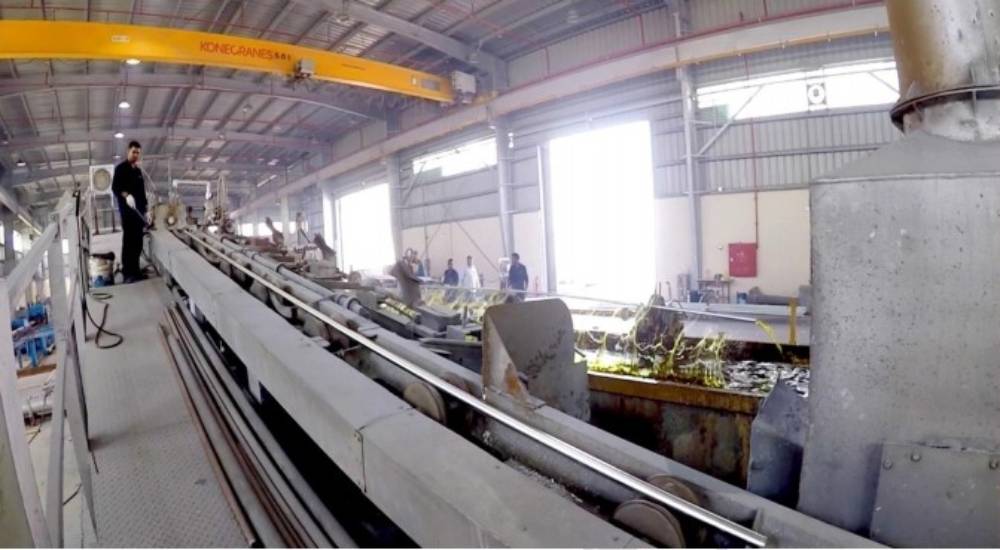

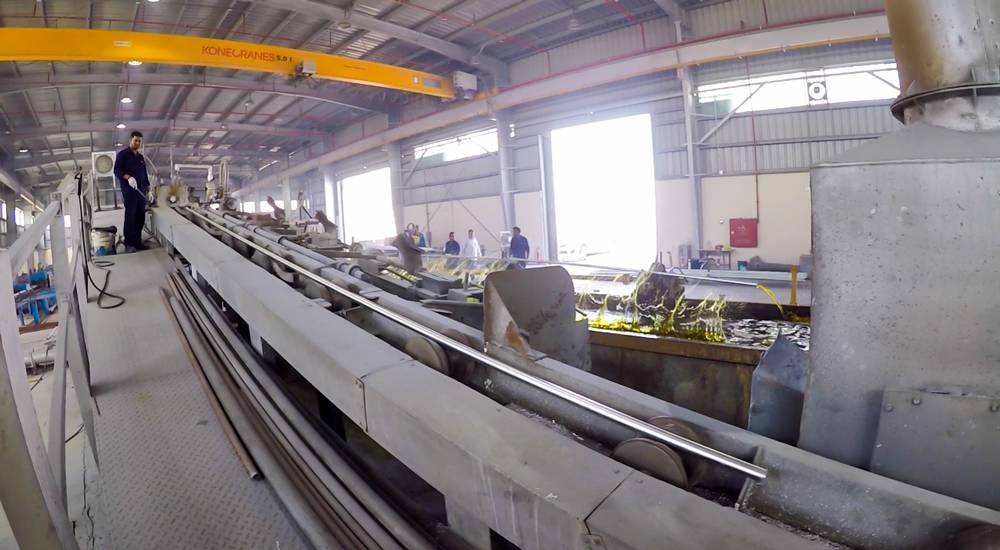

HOT DIP PIPE GALVANIZING PLANT

Hot dip galvanizing plants on the surface of Steel, aluminum and iron metal with zinc coating for long-lasting and quality finishing by professionals as per the client’s need and demand. Hot dip galvanizing plant used in the processing of galvanizing by our organization as Precimax online to deliver the solutions; that’s why our clients appreciate us, and clients’ positive feedback is our main asset. Galvanization involves defensive zinc coating on steels and irons into classify to find rust. Galvanizing equipment is the total option of products, including a hot dip, a crash guard and guard rail, Galvanizing Plant, a General Galvanizing Plant, Galvanizing Plants for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanizing is designed and developed to utilize high-grade raw materials and heavy hot dip Galvanizing machines in harsh conjunction with the industry-set norms and levels. Hot dip Galvanizing is usually very well tested in unique details, so defect-free products are typically sent from consumers’ places. Hot dip Galvanizing gives advantages like a limited pickling period, short manufacturing charge, reduced creation price tag, improved productive.

Introduction

In India, we at NIRMAL OVERSEAS hot dip galvanizing, name it, anything from SRS hot dip galvanizers to a fully equipped hot dip galvanizing plant, can assist you by supplying quality hot dip galvanizing according to your specification.

Nirmal Overseas is a Company devoted to offering exceptional quality of galvanizing services and galvanizing products to the demanding clientele across India. Besides, be it an SRS hot dip galvanizer that you are after, or an indoor hot dip galvanizing service that you are looking for, or the intent to buy an SRS hot dip galvanizing plant, you name it, and we’ve got solutions.

What is a Hot Dip Pipe Galvanizing Plant?

A hot dip pipe galvanizing plant is an industry structure meant for the coating of steel or iron pipes by immersion in molten zinc. It serves to increase the life of metal pipes against rust and corrosion attacks. Our hot dip structure galvanizing plant enables a controlled and uniform coating of zinc, which aids the pipes to be functional and sustainable in rather erratic conditions.

A hot dip pipe galvanizing plant is a process through which steel or iron pipes can be galvanized in this case by immersion of the pipes in molten zinc which helps to increase the lifespan of the metal pipes by preventing them from rusting or corroding. With the hot dip structure galvanizing plant that we offer, the clients are assured of a consistent zinc coverage that helps to achieve optimum performance regardless of the harshness of the environment.

Benefits of Hot Dip Pipe Galvanizing Plant

- Long-Lasting Protection: Zinc Top coating’s durability proves it to be one of the best shields against harsh environmental conditions.

- Cost-Effective Maintenance: Galvanized products are of such nature that they are less prone to needing care therefore cost lowers.

- Sustainability: Galvanizing is a process which can be termed as green as the usage of the steel product is increased.

Features of NIRMAL OVERSEAS Hot Dip Pipe Galvanizing Plant

- Efficient Design: Our plants promote a uniform zinc coating which enhances throughput.

- Customizable Solutions: For both small and large scale operation customized solutions are provided.

- Tough Materials: They are designed to withstand high temperatures and heavy-duty work.

- Simple Usage: The product is intended to be operated easily with little downtime.

- Enhanced Safety Standards: Implements the requirement for safety without affecting operations.

Nirmal Overseas Galvanizing Incorporation is a trusted manufacturer name in the market in India as far as high-class galvanizing companies are concerned.

Advantages of Choosing NIRMAL OVERSEAS

- We have vast experience in delivering high quality galvanizing services through the years.

- Our team of professionals is focused on providing appropriate solutions.

- We don’t charge high prices but maintain high standards.

- We support and serve across the nation and provide our assistance when It’s needed.

Go Looking for galvanizing near me or a galvanizing plant near me? Nirmal overseas is the right place for you.

Applications of Hot Dip Pipe Galvanizing Plant

Our hot dip galvanizing plant is used in a variety of industries, including:

- Infrastructure construction of corrosion resistant pipes.

- Various machinery parts hollow section for square and rectangular machines parts making.

- High strength steel components for heavy industrial projects.

- Pipelines and construction in the substations and energy and utility areas.

Contact Us for Hot Dip Pipe Galvanizing Plant Solutions

For an easier task hot dip galvanizing near me can easily contact NIRMAL OVERSEAS. Or you are in a situation of considering which type of hot dip pipe galvanizing plant fits your requirements, we are eager to help you out in every possible way. More about our hot dip galvanizing services can be found on our website or by calling us.

Service Areas

At NIRMAL OVERSEAS, we serve clients across India, including regions like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Andaman and Nicobar Islands, Chandigarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Jammu and Kashmir, Ladakh, Lakshadweep, and Puducherry.

FAQs

Que 1: What makes NIRMAL OVERSEAS hot dip pipe galvanizing plants better than other companies?

Ans: Hollow Steel Pipe offers its clients durable, efficient plants that are also customized and ensure that the best quality is achieved while galvanizing the items.

Que 2: Can NIRMAL OVERSEAS help me in finding hot dip galvanizing near me?

Ans: Yes, we provide both services and solutions all across India so there is no region which is not covered where our solutions or services are not reachable.

Que 3: What industries can NIRMAL OVERSEAS hot dip pipe galvanizing plant be beneficial to?

Ans: Our company offers hot dip pipe galvanizing plants which can be used in different projects as construction and infrastructure development, manufacturing, automotives and energy including those that require metallic parts that can be protected from corrosive elements.

Que 4: Where do I provide requirements for hot dip galvanizing plant quotation?

Ans: For all inquiries please feel free to reach out through the contact details available on our website. Know what you need and we will work with you to make sure you are provided with a full estimate based on what was needed.