Cut to Length line

OUR OFFICES

KHASRA NO – 134/9/2, VILLAGE-BARHANA TEHSIL-BERI, JHAJJAR HARYANA – 124107

+91-9817975382 / 79

OUR BROCHURE

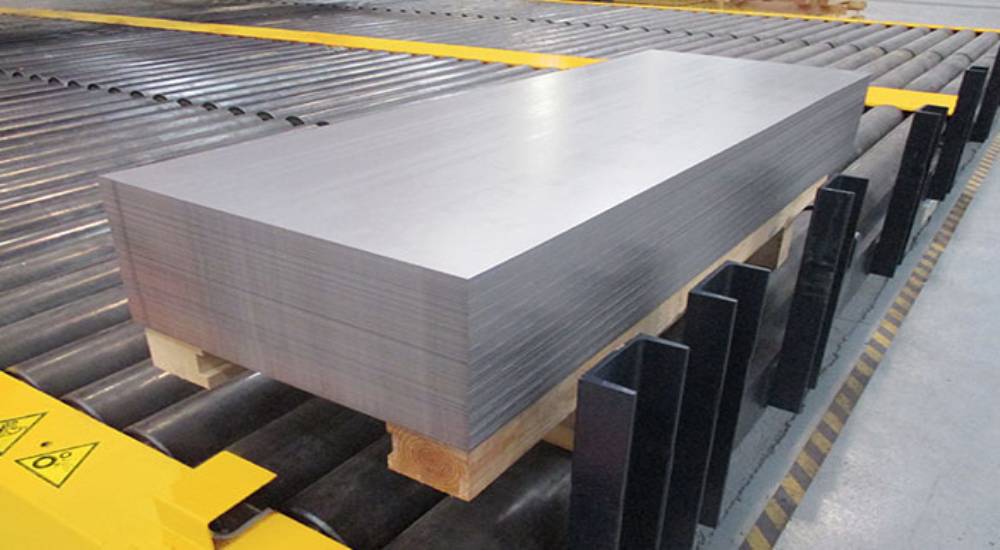

CUT TO LENGTH LINE (1)

CUT TO LENGTH LINE (2)

CUT TO LENGTH LINE (3)

CUT TO LENGTH LINE (4)

| APPLICATION | STEEL PROCESS HOUSE, STEEL & PIPE INDUSTRY, FABRICATION INDUSTRY |

|---|---|

| MIN AND MAX WEIGHT | 5 TON – 35 TON |

| MIN AND MAX WIDTH | 550MM TO 2500MM |

| MIN AND MAX THICKNESS | 0.3 MM TO 20 MM |

| SPEED OF THE MACHINE | 0-20-60-80 METER/MIN |

| RAW MATERIAL USED | HR/CR/SS/GI/COLOUR COATING |

| AUTOMATION LEVEL | FULLY AUTOMATIC |

| TYPE | 2HI, 4HI, 6HI LEVELLER |

Cut to Length line

Cut-to-length lines are used to cut metal strips into sheets and stack them into packages.

Depending on the requirements and productivity, our cut-to-length lines are equipped with fixed cut-to-length shears (stop and go) or flying cut-to-length shears and the appropriate stacking system.

It consists of a double-head decoiler, non-pit sheet guiding device, feeding system, V-notch punching unit, 45°shearing unit, 135°shearing unit, hole punching unit, material stacking system, discharge trolley, control cabinet and operation panel, pneumatic system.

Depending on the required quality, flatness, and surface of the metal sheets, the cut-to-length lines are equipped with our precision levelers, trimming shears, or a foiling device.