HOT DIP PIPE GALVANIZING PLANT

OUR OFFICES

KHASRA NO – 134/9/2, VILLAGE-BARHANA TEHSIL-BERI, JHAJJAR HARYANA – 124107

+91-9817975382 / 79

OUR BROCHURE

| Frequency | 50/60 Hz |

|---|---|

| Phase | 3 Phase |

| Automation Level | Fully Automatic/ Semi-Automatic |

| Pipe Size (Nb) | ½ Inch To 12 Inch |

| Pipe Length | 4 To 12 Meters |

| Zinc Coating | As Per Is & Bs Standard |

| Production Capacity | 2000 To 6000 Tons Per Month |

| Capacity | 4-8 Mt Per Hour For Pipe Galvanising |

| Specification | As Per Api/Is/Astmbs Standard |

| Fuel | Furnace Oil With A Net Calorific Value Of 10000 K. Cal./Kg Or Gas |

| Zinc Consumption | Averages 6 T O 7% Depending On Pipe Size |

| Zinc Efficiency | Average 6 M From Floor Level Zinc Dross: 8 T O 10% |

| By Product Of The Zinc Used | Zinc Dust:10 T O 16% Zinc Ash:16 T O 18% |

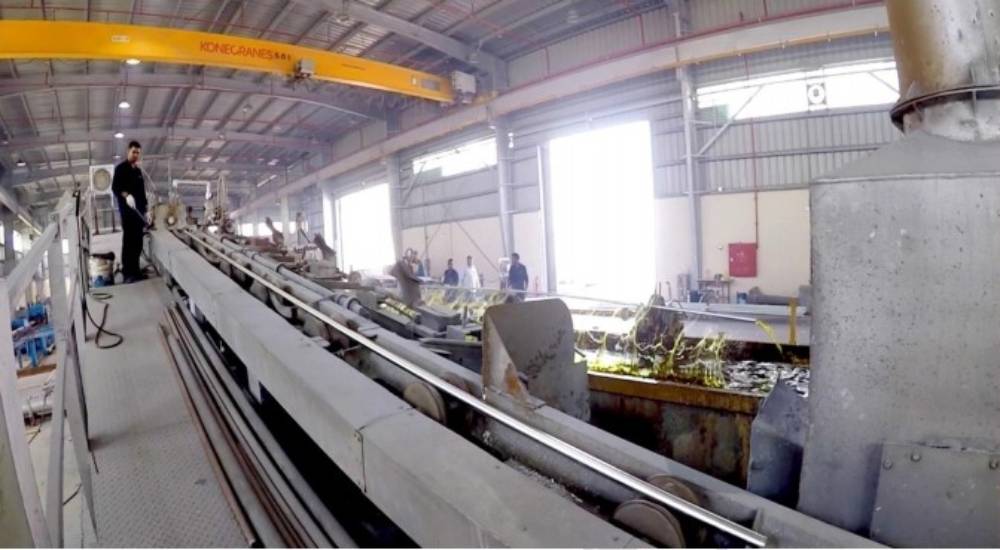

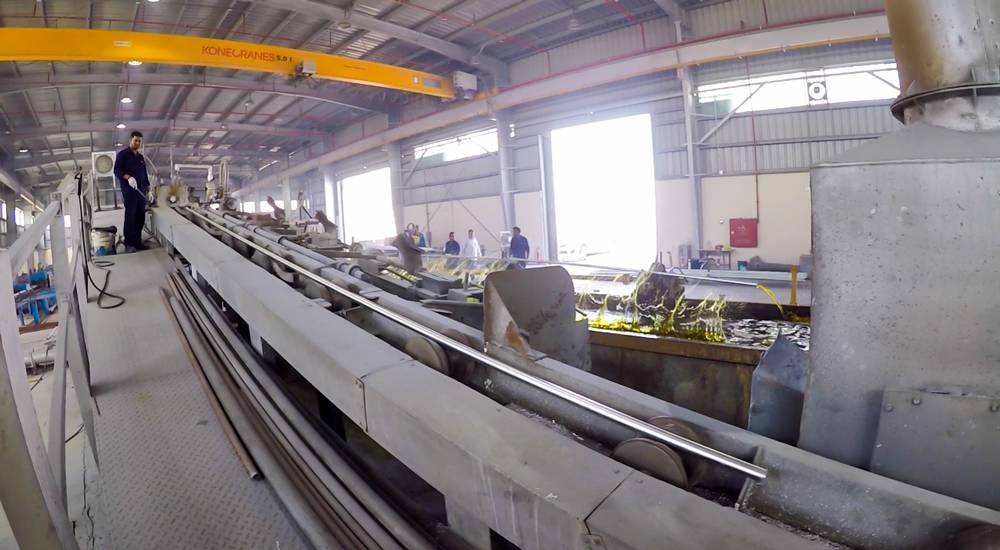

HOT DIP PIPE GALVANIZING PLANT

Hot dip galvanizing plants on the surface of Steel, aluminum and iron metal with zinc coating for long-lasting and quality finishing by professionals as per the client’s need and demand. Hot dip galvanizing plant used in the processing of galvanizing by our organization as Precimax online to deliver the solutions; that’s why our clients appreciate us, and clients’ positive feedback is our main asset. Galvanization involves defensive zinc coating on steels and irons into classify to find rust. Galvanizing equipment is the total option of products, including a hot dip, a crash guard and guard rail, Galvanizing Plant, a General Galvanizing Plant, Galvanizing Plants for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanizing is designed and developed to utilize high-grade raw materials and heavy hot dip Galvanizing machines in harsh conjunction with the industry-set norms and levels. Hot dip Galvanizing is usually very well tested in unique details, so defect-free products are typically sent from consumers’ places. Hot dip Galvanizing gives advantages like a limited pickling period, short manufacturing charge, reduced creation price tag, improved productive.